OBJECTIVES

- To study the effect of different composition of base on the physical characteristic of suppositories.

INTRODUCTIONS

Suppository is a solid formulation that has different size and

appearance and thus is suitable to be administered by rectal route. A good

suppository must be melt after being administered into the rectum and release

the drug content to achieve local or systemic effect. The drug must be spread

in a suitable base of suppository. A good base should be nontoxic, nonirritant,

no reaction with the drug and easily to be formed as a suppository. Different

composition of base will influence the rate and limit of drug release from the

suppository.

APPARATUS

- Analytical balance

- Weighing boat

- Spatula

- 50ml and 100ml beaker

- Hotplate

- 5ml measuring cylinder

- Suppository mould set

- Water bath 37oC

- Dialysis bag

- Glass rod

- 5ml pipette

- Kuvets plastics

- Spectrophotometer UV/Vis

MATERIALS

- Polyethylene glycol (PEG) 1000

- Polyethylene glycol (PEG) 6000

- Paracetamol

- Distilled water

PROCEDURE

Suppository

|

Group

|

PEG 1000

(g)

|

PEG 6000

(g)

|

Paracetamol stock solution (ml)

|

Total

(g)

|

I

|

1,5,9

|

9

|

0

|

1

|

10

|

II

|

2,6,10

|

6

|

3

|

1

|

10

|

III

|

3,7,11

|

3

|

6

|

1

|

10

|

IV

|

4,8

|

0

|

9

|

1

|

10

|

3. The suppository is

shaped using the suppository mould. The shape, texture and color of the

suppository is observed and discussed.

4. The suppository is

placed in the water bath 10ml at 37oC and the time for the

suppository to melt is recorded.

5. The suppository is

placed inside the dialysis bag and placed in the 50ml beaker. The beaker

then placed inside the water bath 37oC.

6. The sample is pipette

in 5 minutes interval and the release of the Paracetamol from the

suppository is determined using the spectrometer UV/Vis. The distilled

water must be stirred first before the sample is taken.

RESULT AND DISCUSSION

1. Compare the physical characteristics of suppositories that formulated and give comment.

2. Plot a graph average time that is required to melt the suppository against different amount of PEG 6000 in formulation. Compare and discuss the results.

3. Plot a graph of UV absorption against time. Explain.

RESULT AND DISCUSSION

1. Compare the physical characteristics of suppositories that formulated and give comment.

Based on the experiment, all the suppositories have the shape of a bullet since the mould that is being used is of this shape. The quantities of PEG 1000 and PEG 6000 different for each group and this will lead to formation of suppositories with different physical characteristics.

For the formulation that has the highest amount of PEG 1000, which means that it has the lowest quantity of PEG 6000 shows the greasiest surface compared to the other suppositories. As for the formulation with lowest amount of PEG 1000 and highest in the amount of PEG 6000, the suppository formed is the hardest of all. The former suppository provide ease to be administered to the patient compared to the latter one and the latter one may lead to pain in the process of administering.

In other words, the higher the quantity of PEG 6000 in a formulation, the less greasy the suppository will be. As for hardness, we can conclude that the higher quantity of PEG 1000 (lower quantity of PEG 6000), will produce softer suppository. As for the colour of suppositories, since the active ingredient that we used is paracetamol which is white in colour, the colour of the suppositories produce will be white but differ in the transparency degree. The formulation with the lowest amount of PEG 1000 is more transparent compared to the others.

2. Plot a graph average time that is required to melt the suppository against different amount of PEG 6000 in formulation. Compare and discuss the results.

Amount of PEG 6000

(g)

|

0

|

3

|

6

|

9

|

Average time (min)

(x +- SD)

|

36.49+-3.96

|

42.78+- 6.22

|

39.68+-6.68

|

37.19+-6.13

|

Base on the experiment, we are using two types of bases which

are polyethylene (PEG) 1000 and polyethylene (PEG) 6000. From the graph obtain

we can observed that the amount of the (PEG) use is not directly proportional

with the time for the suppository to melt. Theoretically, the higher the amount

of the (PEG) used, faster will be the suppository melt. From the experiment

that had been done, it shows that the higher the amount of (PEG), the shorter

the time taken for the suppository to melt. So from the result obtain, it show

that when the amount of (PEG) is 3g the time to melt is the slowest then the

time taken is decrease when the amount of the (PEG) is increased. It is

acceptable with the actual theory, however, for the suppository with absent of

(PEG) in the experiment, it show the lowest time for melt. Supposedly, it must

take the highest time for melt because it did not contain any (PEG) as

co-solvent. We assume that there must be some errors while handling the

experiment especially during compounding the suppository. Besides, error is due

to the temperature of the water bath that we used. Due to different group are

handling different amount of PEG, the temperature of the water bath used must

be not constant because we are using different water bath. So, the water bath

that was used should be constant so that we can get the exact results.

3. Plot a graph of UV absorption against time. Explain.

TIME

(min)

|

Average UV absorption 520nm

|

0

|

0.001

|

5

|

0.018

|

10

|

0.090

|

15

|

0.039

|

20

|

0.105

|

25

|

0.096

|

30

|

0.099

|

35

|

0.088

|

40

|

0.048

|

45

|

0.018

|

50

|

0.052

|

55

|

0.051

|

60

|

0.051

|

During the

experiment, we carry out in vitro test about the release of paracetamol

suppositories against time by using average UV absorption as indicator.

One suppository was put inside the dialysis bag which immersed into the beaker

containing distilled water maintained at 37ºC, which is equal to our body

temperature.The dialysis bag represents human biological membrane while

distilled water represents human blood plasma. The distilled water will enter

into the dialysis bag due to its higher water concentration and suppository

begin to dissolve slowly.The paracetamol then flow out through the dialysis bag into

distilled water and its amount can be detected using UV

spectrophotometer.

Our

formulation of the suppositories use

mixture of 6 polyethylene glycol 1000 :

3 polyethylene glycole 6000.The composition of Polyethylene glycole

plays an important rule in influencing the rate of melting of suppository once

it insert through rectum. The greater the average molecular weights than 1000

, more hardness the waxlike white solids

form and give different melting ranges such as for PEG 1000 is 37’C-40’C and

PEG 6000 is 56’C- 63’C.

Theoritically, the graph should be in sigmoid shape

which indicates constant drug release rate until equilibrium is achieved.Based

on the result, our graph

showing gradually increase in uv absorption which indicates that the

drug is releasing slowly for PEG formulation but

however it decrease slighly and increase back until the constant values achieved

at the end of 60 minutes. Our graph deviates from the theory may be because of

errors that occurred when we conduct the experiment. The first error we

detected is uneven heating of water bath due to the high frequency of removing the cover of hot plate

makes the temperature of water does not maintain at 37ºC which will

lead to inconstant drug release rate from the suppository. Moreover, some of

water in water bath had incidentally spill into the beaker making the volume

increases and affect the concentration of paracetamol. Besides that,distilled

water in which the dialysis bag is exposed to may not be stirred evenly before

it is taken to be tested on UV spectrophotometer.

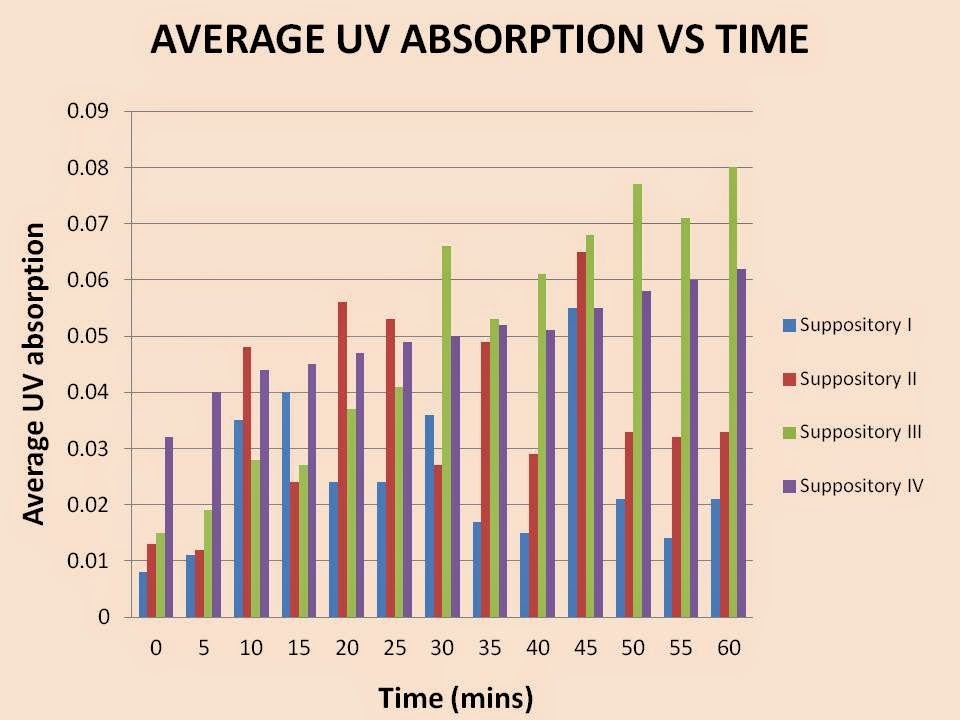

4. Plot

a graph of UV absorption for different composition of suppository formulations

against time. Compare and explain the results.

Time (min)

|

Average UV absorption at 520 nm ( x ± SD )

|

||||||||||||||

0

|

5

|

10

|

15

|

20

|

25

|

30

|

35

|

40

|

45

|

50

|

55

|

60

|

|||

UV absorption at 520nm

|

I

|

Group 1

|

0.003

|

0.006

|

0.053

|

0.054

|

0.028

|

0.029

|

0.050

|

0.012

|

0.008

|

0.012

|

0.022

|

0.005

|

0.018

|

Group 5

|

0.012

|

0.016

|

0.016

|

0.026

|

0.019

|

0.018

|

0.021

|

0.021

|

0.021

|

0.097

|

0.020

|

0.022

|

0.024

|

||

Average

|

0.008

|

0.011

|

0.035

|

0.040

|

0.024

|

0.024

|

0.036

|

0.017

|

0.015

|

0.055

|

0.021

|

0.014

|

0.021

|

||

SD

|

0.0064

|

0.0071

|

0.0262

|

0.0198

|

0.0064

|

0.0078

|

0.0205

|

0.0064

|

0.0092

|

0.0601

|

0.0014

|

0.0120

|

0.0042

|

||

II

|

Group 2

|

0.001

|

0.018

|

0.090

|

0.039

|

0.105

|

0.096

|

0.044

|

0.088

|

0.048

|

0.098

|

0.052

|

0.051

|

0.051

|

|

Group 6

|

0.025

|

0.006

|

0.006

|

0.008

|

0.007

|

0.010

|

0.010

|

0.009

|

0.009

|

0.032

|

0.013

|

0.012

|

0.015

|

||

Average

|

0.013

|

0.012

|

0.048

|

0.024

|

0.056

|

0.053

|

0.027

|

0.049

|

0.029

|

0.065

|

0.033

|

0.032

|

0.033

|

||

SD

|

0.0170

|

0.0085

|

0.0594

|

0.0219

|

0.0693

|

0.0608

|

0.0240

|

0.0559

|

0.0276

|

0.0467

|

0.0276

|

0.0276

|

0.0255

|

||

III

|

Group 3

|

0.026

|

0.032

|

0.029

|

0.024

|

0.032

|

0.037

|

0.067

|

0.042

|

0.047

|

0.052

|

0.055

|

0.058

|

0.060

|

|

Group 7

|

0.004

|

0.006

|

0.026

|

0.030

|

0.042

|

0.045

|

0.064

|

0.063

|

0.075

|

0.083

|

0.099

|

0.083

|

0.100

|

||

Average

|

0.015

|

0.019

|

0.028

|

0.027

|

0.037

|

0.041

|

0.066

|

0.053

|

0.061

|

0.068

|

0.077

|

0.071

|

0.080

|

||

SD

|

0.0156

|

0.0184

|

0.0021

|

0.0042

|

0.0071

|

0.0057

|

0.0021

|

0.0148

|

0.0198

|

0.0219

|

0.0311

|

0.0177

|

0.0283

|

||

IV

|

Group 4

|

0.060

|

0.075

|

0.080

|

0.084

|

0.087

|

0.091

|

0.093

|

0.095

|

0.094

|

0.102

|

0.106

|

0.107

|

0.109

|

|

Group 8

|

0.004

|

0.005

|

0.007

|

0.005

|

0.006

|

0.006

|

0.006

|

0.009

|

0.007

|

0.007

|

0.009

|

0.012

|

0.014

|

||

Average

|

0.032

|

0.040

|

0.044

|

0.045

|

0.047

|

0.049

|

0.050

|

0.052

|

0.051

|

0.055

|

0.058

|

0.060

|

0.062

|

||

SD

|

0.0396

|

0.0495

|

0.0516

|

0.0559

|

0.0573

|

0.0601

|

0.0615

|

0.0608

|

0.0615

|

0.0672

|

0.0686

|

0.0672

|

0.0672

|

||

Different suppository

base compositions will have different effects on the drug release rate over

time. In this experiment, we varied the ratio amount of PEG 1000 and PEG 6000

in each of the suppository. From suppository

I to suppository IV, the average UV absorbance should increase all the time

following this order as the amount of PEG 1000 decreasing while amount of PEG

6000 increasing in this order.

Suppository I has the

highest amount of PEG 1000 and none PEG 6000. According to the theory, it

should be showing the highest drug releasing rate as well as the UV absorption.

This is due to lesser hydroxyl group present in PEG 1000. Thus, there are less

strong hydrogen bond formed between the molecules of PEG 1000 and molecules of

paracetamol. Little energy would be needed to break the bonds to release the

drug. Hence, it would have a higher releasing rate. Higher releasing rate would

cause the UV absorption to be higher.

On the other hand,

Suppository IV has the highest amount of PEG 6000 with none PEG 1000. It has

more hydroxyl groups present in it. Thus, there are more hydrogen bonding

formed between the molecules of PEG 6000 and the molecules of the paracetamol

when they are mix together and formed a suppository. It has the highest

molecular weight. Highest molecular weight would cause a lower drug releasing

rate. Therefore, a longer time and higher energy is needed in order to break

down the strong hydrogen bond and subsequently release the drug. This will

result in longer drug releasing time and lower the drug releasing rate. This

will further lower the UV absorption.

Suppository II and

Suppository III has intermediate UV absorption. Suppository II has higher UV

absorption than Suppository III as Suppository II has higher PEG 1000 but lower

PEG 6000 than Suppository III. Thus, there are less hydrogen bond formed

between the Suppository II bases and paracetamol. Less energy would be needed

to break the bonds to release the drug. Hence, it would have a higher releasing

rate than Suppository III. Higher releasing rate would cause the UV absorption

of Suppository II to be higher than Suppository III.

However,

according to our graph, we can see that Suppository III has the highest UV absorption,

while, Suppository I has lowest UV absorption rate, which indicates that it has

lowest drug releasing rate. Meanwhile, Suppository II and Suppository IV show

intermediate UV absorption. This did not comply with the actual theory. Besides

that, the graph showed deviated much in comparison between results of each two

groups. It is due to many errors arisen in the experiment. These errors can be

due to the improper method of compounding, non-homogenous dispersion of

Paracetamol in the PEG suppository base, inaccuracy of the UV spectrometer, and

so on. Other errors that may occur include inconsistency in temperature which

may affect the drug release from the suppository, the sample in the beaker did

not stir well before pipette out from the solution or could be due to dirt or

impurities present in the cuvettes which are used to fill the sample and hence

lead to deviation of the result.

5. What is the function of each

ingredient that is used in the preparation of these suppositories? How does the

usage of different content of PEG 1000 and PEG 6000 affect the physical

properties of suppository formulation and rate of releasing of drug from it?

PEG

6000 act as suppository bases.The Paracetamol that is used in the

preparation of the suppository acts as the active ingredient. It is the main

substance in the drug formulation which has the major role in contributing to

the required drug therapeutic effects in the body.

The

use of different contents of PEG 1000 and PEG 6000 results in different effects

on the physical characteristics, subsequently affecting the rate of drug

released from the suppository. More hydrogen bonds are formed between the PEG

6000 molecules and drug molecules when the more PEG 6000 is used. This will

result in the increase of the hardness of the suppository and also the

difficulty of the drug released from the suppository. Besides that, the

production of dry, hard, smooth, coarse, tackier and clear white suppository

will be obtained.

Hence,

it is important to choose the correct combination ratio of PEG 1000 and PEG

6000 to avoid the production of extremely hard or soft suppository and to

ensure an optimum bioavailability of the drugs can be obtained.

As

the proportion of PEG6000 increases, the drug becomes more difficult to be

released from the suppository.

CONCLUSION

Different percentage of combination of PEG

1000 and PEG 6000 affects the physical characteristics of the suppository and

the rate of release of the active ingredient.

REFERENCES

- https://www.inkling.com/read/ansel-pharmaceutical-dosage-form-drug-delivery-9th/chapter-12/suppository-bases

- http://www.drugs.com/inactive/polyethylene-glycol-6000-274.html

Tiada ulasan:

Catat Ulasan